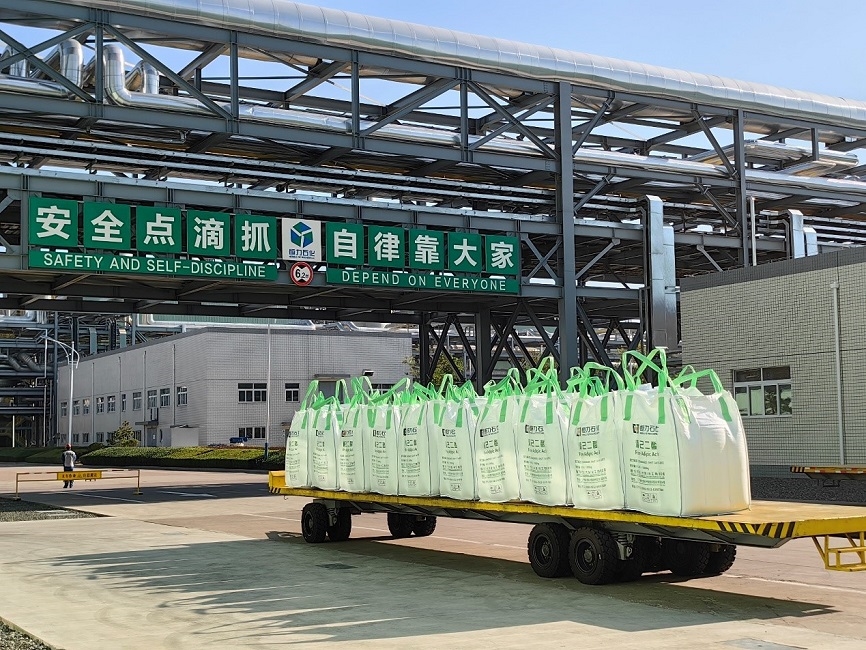

Recently, the 300,000 t/a adipic acid drying project of Hengli Petrochemical (Dalian) New Materials Technology Co., Ltd. (hereinafter referred to as “Hengli Petrochemical”) undertaken by the Drying Equipment Department of Tianhua Institute of Chemical Machinery & Automation Co., Ltd. (Tianhua Institute) went into operation successfully and produced first-rate adipic acid products.

As one of the major technical production units of the supporting chemical project of Hengli Petrochemical, the 300,000 t/a adipic acid unit is designed to produce high-end adipic acid by using cyclohexanol and dilute nitric acid as raw materials. By relying on the joint research center for low-carbon energy and energy-saving equipment established by Tianhua Institute and Hengli Petrochemical in 2022, the project adopted for the first time the new “dry” technical process, which is greener and lower-carbon than the current drying technological process.

As a type of important organic binary acid, adipic acid (AA) is widely used. It is mainly used as raw material of nylon 66 and engineering plastics, as well as of various esters, polyurethane elastomer and acidifier of foods and beverages. In addition, it can be used as raw material of medicine, yeast extract, pesticide, adhesive, synthetic leather, synthetic dyestuff and spice.

Adipic acid tends to generate static electricity, soften and cake at a high temperature, absorb moisture to form lump and chalk and is difficult to be dried. Nevertheless, the adipic acid drying unit has been gone into operation thanks to Tianhua Institute’s one-month painstaking efforts for commissioning tests. By using the “dry” technical process developed by the joint research center, the project has achieved cascade utilization of the energy of hot water and vapor, saving energy by over 20% and water by over 90% compared with the current drying technological process.

The smooth operation of the project indicates the successful operation of the new “drying” drying technical process, accumulating valuable experience in drying similar materials and further promoting green and low-carbon development of the adipic acid industry.

(Correspondent: Si Huanhuan)