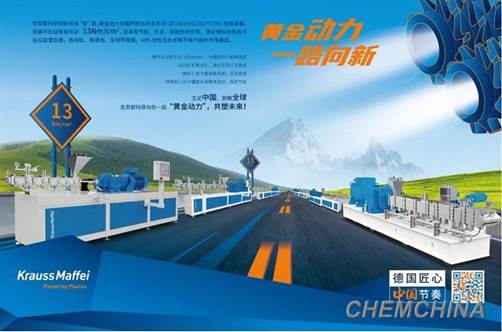

On July 16, 2021, KraussMaffei, one of the world’s leading manufacturers of rubber and plastic production, processing machinery and systems and an overseas subsidiary to China National Chemical Equipment Co., Ltd., held its Pioneers Day themed “Gold Power for Sustainability” to unveil its full series of gold-power twin-screw extruders in its Jiaxing Integrated Factory. The twin-screw extruder series released this time feature excellent performance, with the torque/maximum total mass ratio reaching 13Nm/cm3. Many technological breakthroughs have helped KraussMaffei set a new exemplar in the compounding equipment industry. The extruders are also another batch of masterpieces of KraussMaffei in leveraging global resources, expanding market and continuously enhancing its local R&D capabilities.

Guests visit the KraussMaffei Technology Center

Flexible and efficient solutions for the diverse needs of the compounding market

In response to the growing customer demands and new market applications, KraussMaffei has launched a full series of twin-screw extruders, which is a new generation of products manufactured with the world’s leading technology, local innovation and R&D, and a host of technological innovations. The full series of models amounting to 13Nm/cm3 can adapt to more applications and improve production and performance. Unique 4D and 6D cylinders can be used to realize accurate temperature control. The C-shaped chuck flange system facilitates the assembly and disassembly of cylinders, greatly saving the installation time for cylinder replacement. The new generation of Gold Power ZE26/34/52/62/77/95 for different applications with their highlights have been designed to meet the increasingly diverse market needs of the compounding market, provide customers with stable, efficient and flexible solutions.

— ZE26, small but extraordinary. For the experimental model for material testing, the size ratio of mass-production machines is reduced proportionally. As their component design and functions are retained, the high stability and the easy-to-monitor process can better meet the experimental requirements.

— ZE34, colorful and outstanding. ZE34 can better meet the needs of the color masterbatch industry, especially those of small-scale samples and mass production in the field of PET fiber-spinning color masterbatch, with remarkable quality. ZE34 has been a cost-effective masterbatch production solution for customers.

— ZE52, highly adaptable. ZE52 has been mainly applied in plastic modification to improve the stable quality of modified material products and increase the output significantly. It can fully meet the high-quality needs of nylon and glass fiber products for the automotive industry and of PC/ABS alloy products for the electronics industry.

— ZE62, high precision. ZE62 can be used to provide customers with technical solutions for high filling masterbatch production lines to meet the stringent requirements of feeding, cylinder sealing and torque in the production of waterproof and breathable films to ensure high quality production.

— ZE77, sustainable. ZE77 featuring flexible extrusion coupled with the mature process of screw combination can be applied in the modification of biodegradable biomaterials such as PLA, PBAT, PBS, PHA, PCL and other plastic substrates, covering agriculture, food packaging, tableware, logistics, and textile.

— ZE95, basic but essential. Focusing on the mass production of plastic pellets, ZE95 has been widely used in plastic modification and synthesis, recycling, and biodegradability, covering ABS modification and synthesis, and modification and granulation of PBAT biodegradable materials.

Full series of Gold Power twin-screw extruders for innovative and flexible applications

Also, the new generation of Gold Power extruders have been operated at a speed of 600 rpm or 900 rpm. KraussMaffei’s advanced experience over screw combinations and process technologies like lateral evacuation has supported customers in attempting innovative applications and opening up new markets.

Local innovation and upgrading for new markets and applications

Liu Tao, chairman and general manager of China National Chemical Equipment Co., Ltd. and chairman of KraussMaffei, attended the event, delivering a welcome speech. Chairman Liu thanked all guests, customers and partners for their support and congratulated KraussMaffei’s Chinese team for its new achievements in pioneering new products, applications and markets.

Liu Tao, chairman and general manager of China National Chemical Equipment Co., Ltd., gives a welcome speech

At the Pioneer Day event, the KraussMaffei Extrusion Technology Center was equipped with the new equipment for the complete production lines of ZE52 and ZE26 and a set of imported Blue Power 42 complete lines to demonstrate the performance and application of the equipment. It also showcased the Technology Center's ability to provide customers with hands-on innovations and applications and flexible processes and technologies.

President Sun Zhongxin of Tianhua Institute of Chemical Machinery & Automation Co., Ltd., a subsidiary of KraussMaffei, came to the Pioneer Day to share the technical advantages and application characteristics of “Lantai Plastic Machinery” and discuss the market trend of compounding. The Pioneer Day also marked the formal integration between KraussMaffei and Tianhua Institute, which can share resources and play a more synergistic role in technical services and innovative applications.

“As innovation leads upgrading, KraussMaffei has been a worldwide technology pioneer in the field of compounding, never ceasing its pace of R&D and innovation. The launch of the full series of Gold Power products represents another milestone in China's local R&D and innovation. KraussMaffei is full of confidence in the future of the compounding market. It will continue to base itself on China and set its sights on the world to deliver more new products and applications to a wider market.” said Cui Xiaojun, general manager of KraussMaffei China.

Currently, the Gold Power series are going through CE certification. In the near future, the smart series made through China’s innovation and R&D will found their presence in the global market.

Since its official opening in June 2020, KraussMaffei’s Jiaxing Integrated Factory has been improving its capabilities of local R&D and innovation, launching a series of new influential products with state-of-the-art technologies in the industry, including the newly released Gold Power twin-screw extruder. Customers visiting the Technical Center and the workshop on the day of the Pioneer Day were keenly interested in inquiring about the application technology and features of new Gold Power products and discussing with KraussMaffei’s staff over the industry trend and application of the compounding technology. Going forward, KraussMaffei will continue to make innovations and commit itself to developing Gold Power products with its industry partners to shape the future.