At K 2022, KraussMaffei officially released its “Additive Manufacturing” solution, which became its fourth key technology in addition to plastic injection molding, extrusion and reaction injection molding. The solution can be used to manufacture large and structurally-complicated plastic parts, and small plastic parts that have high requirements on surface quality and precision, thereby creating new market opportunities for customers in such industries such as medicine, construction and casting, etc.

As KraussMaffei’s fourth key technology, Additive Manufacturing (3D printing) has provided new opportunities for manufacturing of plastic products and attracted wide attention from the market. The century-old injection molding and extrusion technologies and practices have laid a solid foundation for KraussMaffei to develop all-new “Additive Manufacturing” solutions. As two brand-new systems of KraussMaffei’s latest “Additive Manufacturing” technology, powerPrint and precisionPrint can be used for printing of large-size parts and volume production of individual parts and advancing the development of all industries in the future.

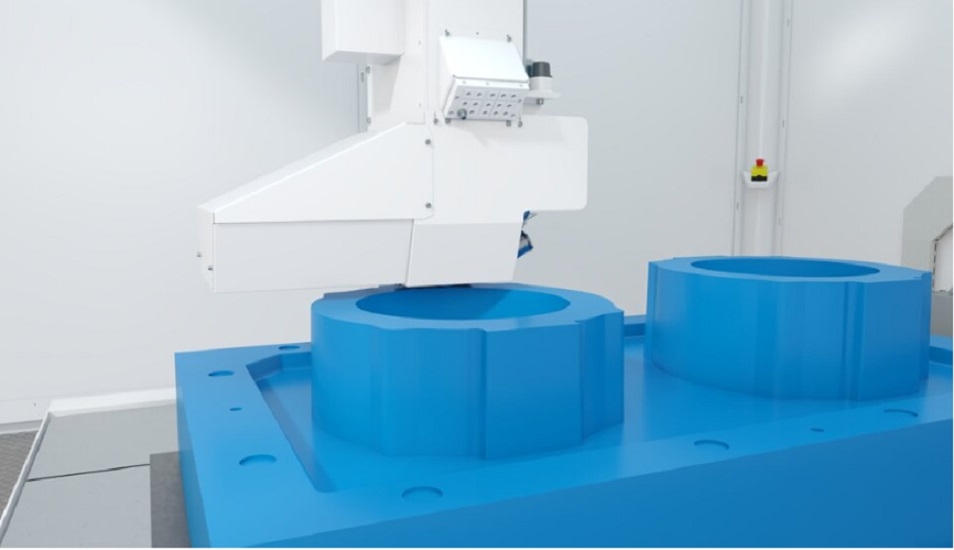

powerPrint can print large parts easily.

powerPrint can print large-size parts rapidly and effectively

As an extruder-based printing system, powerPrint is used to process thermopalstic granules and is suitable for “Additive Manufacturing” of plastic parts with a large size up to 10 cubic meters. The printing system can optimize the performance of plastic parts, reduce the material costs, fit with general-purpose software solutions, reduce the time of equipment testing and operation, and increase output efficiency and rate of return. powerPrint is usually used for on-demand solutions or the industries of rapid production of near-end parts. It is applicable to large part printing in such industries as the foundry, furniture, construction, and public infrastructure, in addition to mold making.

precisionPrint is used for precision printing of “small parts”

The groundbreaking precisionPrint laser system helps low-cost production of small parts

As a high-performance light-curing molding solution, the precisionPrint printer is applicable to mass and low-cost customized production. Its precise end-to-end system ensures that the surface of printing components meets the requirements on ultra-high precision and production of high-quality small-size parts. It is particularly suitable for such industries as medical care, electricity & electronics, and leisure sports, etc., involving hearing aid, connector, and shoe sole, etc.

“Additive Manufacturing” has many advantages ranging from prototyping to full-scale industrial production of plastic parts. It causes almost no loss to materials and increases the design flexibility. In the future, KraussMaffei will continue to explore the “Additive Manufacturing” market and join hands with its partners to enhance the product added value and empower the high-end manufacturing.