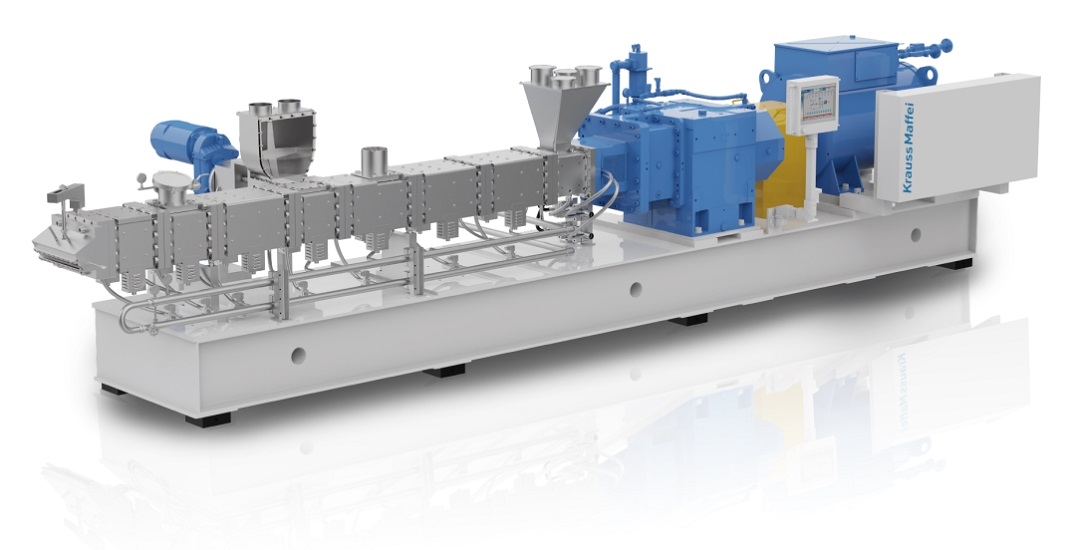

KraussMaffei's Pioneer Power™ foam extrusion line has been put on the market recently, which is another solution launched by the company in this field. KraussMaffei has always been known for its cutting-edge technology and rich industry experience in the field of foam extrusion. It provides reliable, stable, efficient and high-performance foam extrusion equipment for plastic plates, sheets, pipes and profiles. Adopting a physical foaming process, the brand-new Pioneer Power™ form extrusion line connects twin-screw and single-screw extruders in tandem, which perfectly combines the mixing technology of ZE95 twin-screw extruder with the efficient cooling performance of KE250 single-screw extruder.

In this production line, polymer particles and additives (nucleating agent, chain extender, flame retardant, etc.) are completely melted and mixed in the barrel of twin-screw extruder, and foaming agents (usually alkane, liquid supercritical carbon dioxide or mixed foaming agent) are quantitatively injected at a constant pressure. After mixing, dispersing, distribution homogenization, cooling, and pressure building, high-quality foamed sheets are finally obtained through the steps of single-screw extruder die extrusion, shaping traction and subsequent cooling and processing. The production line can be applied to products such as foam sheets for the packaging and construction industries, pressure and moisture resistant insulation panels, XPS insulation panels for basement walls, rotor blade sandwich material - PET foam panels, etc. KraussMaffei can customize the corresponding upstream and downstream processing equipment and provide a complete turnkey system according to customers’ requirements to ensure the integrity and fit of the whole line.

Single-screw extruder KE250

KraussMaffei's KE series single-screw extruders feature active melt sealing technology that enables the foaming agent used in the foaming process to remain stable at high concentrations and high system pressures, thus ensuring high product quality. At the same time, these extruders offer excellent cooling capacity to ensure melt quality, with an absolutely stable temperature control, barrel and "liquid" bushing optimization system to efficiently remove heat and cool the melt with a unit cooling capacity of 145 (kg/h)/m². This function is based on precise calculations and simulations for targeted cooling tasks, and its special geometry reduces energy consumption by more than 30%. A precise temperature control system inside the entire screw ensures uniform cooling of the melt.

Golden power twin-screw extruder ZE95

The Golden Power ZE95 twin-screw extruder has flexible barrel design with 4D and 6D structures, and its eight different barrel components ensure the flexibility of barrel length. At the same time, KraussMaffei has optimized the screw combination, using HIP highly wear-resistant and corrosion-resistant materials and 27 different threaded elements to provide unlimited design possibilities. The raw materials are subjected to much smaller shear forces when mixed uniformly, resulting in smaller and more evenly distributed bubble holes in the foamed sheet or plate. The screw and barrel follow a modular design concept and can be configured to meet specific process requirements. The excellent meshing system also ensures an excellent mixing effect. The Golden Power ZE95 twin-screw extruder is also equipped with an efficient and easy-to-use intelligent control system, which not only allows real-time monitoring of the production process, but also provides good data traceability for production adjustment and maintenance.

With the promotion of the national dual-carbon goal, the sheets/plates/boards/panels used in construction and infrastructure are required to be lighter, greener and more functional. As an important way to reduce the weight of polymer materials, the role of foaming is increasingly crucial. Supercritical fluid foamed polymers are safe and green, and their excellent thermal insulation, mechanical properties and low-carbon features meet the needs of rapidly developing emerging industries and high quality of life, showing a quite promising market outlook. In the future, the KraussMaffei Pioneer Power™ foam extrusion line will continue to help the PET, XPS and PE panel industries to become lighter and greener, empowering customers with higher, finer and more flexible processing technology for easy operation and stable production, and providing strong impetus to the production of high-quality products with higher yield and ROI.