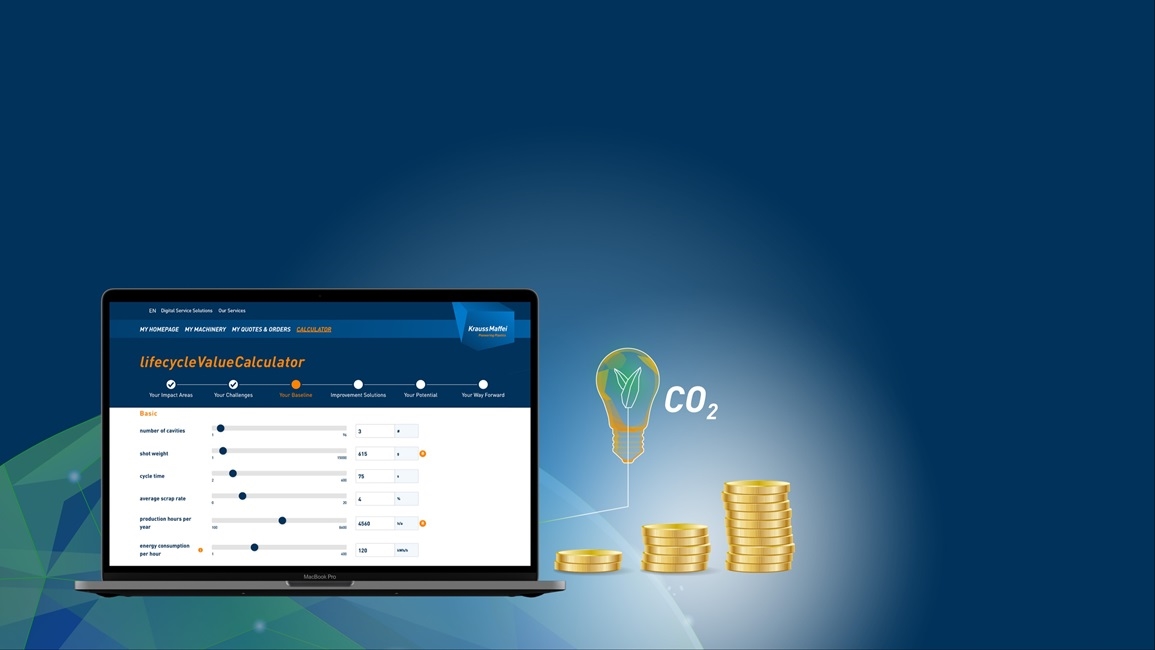

(Munich, 9th October 2023) Investment decisions are often only about capital expenditures (CAPEX). However, by far the majority of costs occur in the operation phase of a machine. A new calculation tool from KraussMaffei makes the economic and ecological impact of a machine, a digital service product or a lifecycle service product visible over its product lifecycle. In this way, the lifecycleValueCalculator supports plastics processors to meet their CO2 targets and increase profit at the same time. As a pioneer in the plastics processing industry, KraussMaffei offers one of the first comprehensive value calculation tools.

Basically, it's like an iceberg: only the tip is visible above the surface, the vast majority of its mass lies underwater. The same applies to the total product lifecycle costs e.g. of injection molding machines. 80 to 90 percent of those occur in the operation phase (OPEX), e.g. for energy consumption, material, maintenance or downtime, but are mostly not quantified in detail. The situation is similar with CO2 emissions: Here, 60 to 70 percent of the CO2 emissions occur during the operation phase. “This means that the greatest potential for economic and ecological optimization is not immediately apparent,” explains Markus Lunz, Head of Service Product & Portfolio Development.

The new lifecycleValueCalculator by KraussMaffei makes this potential visible. With the calculation of individual ecological impacts from production, the tool also supports in the fulfillment of increasingly strict legal regulations and documentation requirements regarding ecological aspects. Especially various national regulations, requirements for recycled material quotas, the digital product passport as well as indirect influences on external financing triggered by the EU taxonomy require a high transparency on ecological impacts.

Functionality

The lifecycleValueCalculator guides its users through the calculation in six simple steps, taking individual production parameters into account. The calculation starts with a concrete challenge of the user, e.g. fluctuations in material quality or changing environmental conditions leading to increased scrap rates. As a first result the calculation creates transparency about the individual economic and ecological as-is-situation, e.g. regarding CO2-emissions, energy consumption, scrap related costs or lost revenue due to downtime. Afterwards the tool quantifies the specific improvement potential by using KraussMaffei solutions which meet the customers’ challenges. In this way, the individual economic and ecological value of a KraussMaffei solution can be determined.

D2-strategy: Decarbonization powered by Digitalization

Digitalization paves the way to sustainability by collecting, monitoring, analyzing and validating data to take concrete actions for improvement. Digital service products enables prediction to proactively react even before problems occur. In this way it is possible to determine and optimize CO2 emissions (decarbonization) while reducing costs for e.g. energy. “This is the heart of our D2-strategy”, Volker Ganz, Vice President Customer Excellence & Global Service Operations explains. “We strongly believe that economic business goals can only be achieved by reaching ecological goals at the same time. In this way, digital service products directly help our customers in meeting ecological targets. The lifecycleValueCalculator is an example of how digitalization supports decarbonization by creating transparency about CO2 emissions.”

The lifecycleValueCalculator is the latest module in the pioneersClub, the customer portal of KraussMaffei. As a web-based solution, only a registration under pioneersclub.kraussmaffei.com is necessary. Currently, the calculator is already available free of charge in most European countries and North America and covers injection molding, extrusion and reaction process technology. More countries will follow soon.